Magnesium Oxide Board

Suparna has been producing quality MgO board for over 20 years. MgO board is an upgraded product that replaces wood board and gypsum board. The service life of Suparna MgO board can reach at least 25 years for indoor application.

- Color: white/grey

- Size: 1200*2400mm/1200*3000mm/1200*2700mm/customized

- Thickness: 3-40mm

- Edge: square/tongue and groove/tapered

- Surface: smooth/sanded

- Fireproof Grade: A1

|

Density (dry at 40°C) (EN 322:1993) |

900kg/m 3 (+/- 10%) |

|

Modulus of Elasticity E Flexion (BS EN 310:1993) |

3596 N/mm2 (9mm board) |

|

Thickness Tolerances |

±1mm |

|

Length Tolerances |

±2mm |

|

Width Tolerances |

±2mm |

|

Squareness on panel diagonal difference |

±2mm |

|

Breaking Strength (MOR) (BS EN 310:1993) |

4.97N/mm2 (9mm board) |

|

Tensile strength (Thickness) (BS EN 319:1993) |

1.64N/mm2 (9mm board) |

|

Thermal Conductivity |

0.27 W/m°K |

|

Compression Strength (min) |

7.07N/mm2 |

|

Moisture Content (ex production) (EN 323:1993) |

12% ± 5 by weight |

|

Reaction to Fire (EN 13501-1) |

A1 |

|

Thickness Swelling (EN 317) |

0.6% |

|

Dimensional Stability |

<0.1% |

|

Acoustic Absorption |

aw=0.10 |

|

Water Vapour Permeability |

9mm – 0.0149 gm/MNs |

|

Vapour Resistivity |

9mm – 67 MNs/gm |

|

Vapour Resistance |

9mm – 0.7 MNs/g |

In order to make sure of stable quality, Suparna adheres to strict product quality standards and has its products certified. At present, we have CE and ISO9001 certificates, SGS test reports for halogenide resistance and component analysis.

Suparna values customer’s demand most. So far, we served customers from Europe, America, Asia and many other districts. To ensure the smooth promotion of the business, apart from the above existing certificates and test reports, Suparna can also provide other certificates according to customer’s requirements and regulations of importing country.

Our Recent Projects

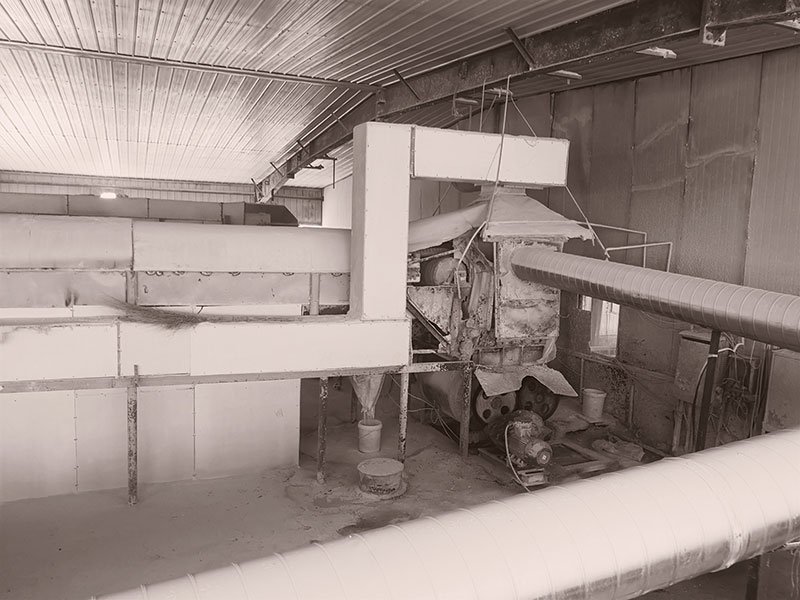

Production Line

Material Preparation

Input data of raw materials according to the formula

Mixing

Transfer raw materials to the mixer and mix them evenly

Board Production

Add non-woven fabric, fiberglass mesh and slurry to make board

Curing Phase I

Control temperature and humidity to solidify the board

Demolding

Use the demolding machine to separate board from the template

Curing Phase II

Boards warm up due to chemical reaction for about seven days

Soaking

Soak the boards into pools for releasing chemicals that shorten the service life

Drying

Place boards under the sun until they are completely dry and turn white

Cutting

Use machine to cut boards into smaller pieces according to the requirements