I. Overview

This article shows the way to test the halogenide resistance of magnesium oxide board. We used Suparna MgO boards as samples to do a 15-day test and the result was quite satisfying.

II. Summary of Test Results

|

No. |

Test Item | Test Method | Result | Conclusion |

| 1 | Halogenide Resistance | With reference to JC 688-2006 Section 6.2.7 and client’s requirement | See results |

/ |

Note:

- Pass: Meet the requirements;

- Fail: Does not meet the requirements;

- /: Not Apply to the judgment.

III. Test Description

1. Test item: Halogenide resistance

2. Sample description: See photo below

3. Test method:

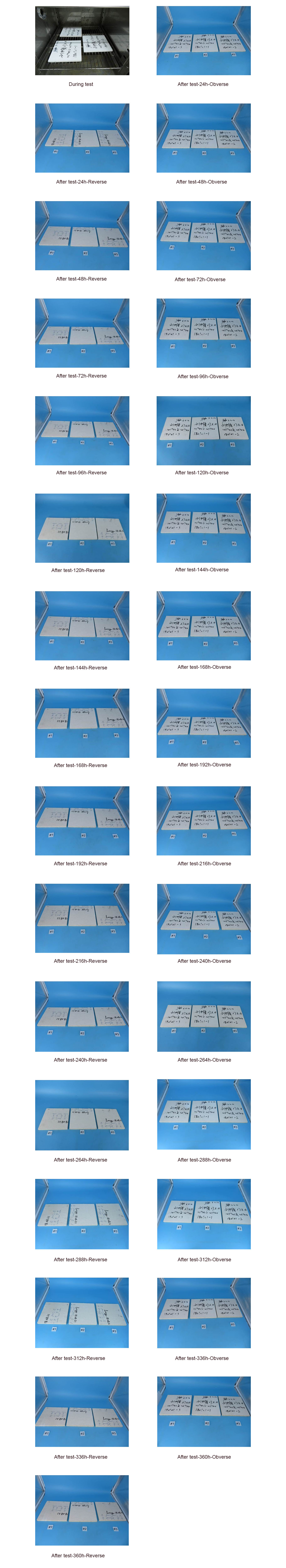

Cut boards of 200*200 mm on each of the three sample MgO boards.

Put them into a constant temperature and humidity chamber with a relative humidity of 90% or more and a temperature of 30-35 °C.

Take them out after 24 hours to see if there is any water drops or moisture.

4. Test condition: 30~35℃, 90%RH, 15 days

5. Equipment information:

| Equipment | Model | Equipment No. | Calibration Date | Next Calibration Date |

|

High/Low Temperature Cyclic and Damp Heat Chamber |

EL-02KA | GZMR-AG-E081 | 2017-11-14 | 2018-11-13 |

| Electron Balance | PL2002 | GZMR-AG-E125 | 2018-06-20 | 2019-06-19 |

IV. Test Results:

| Samples | Exposure Period | Mass, g | Appearance |

| Sample A-#1 | 0h | 483.72 | / |

| Sample A-#2 | 470.35 | / | |

| Sample A-#3 | 475.59 | / | |

| Sample A-#1 | 24h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 48h | 510.93 | No damp or droplet |

| Sample A-#2 | 497.97 | No damp or droplet | |

| Sample A-#3 | 504.22 | No damp or droplet | |

| Sample A-#1 | 72h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 96h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 120h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 144h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 168h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 192h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 216h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 240h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 264h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 288h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 312h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 336h | / | No damp or droplet |

| Sample A-#2 | / | No damp or droplet | |

| Sample A-#3 | / | No damp or droplet | |

| Sample A-#1 | 360h | 521.10 | No damp or droplet |

| Sample A-#2 | 507.47 | No damp or droplet | |

| Sample A-#3 | 512.87 | No damp or droplet |

Note: Intermediate inspection was carried out within 5 mins after specified duration and the result is only for client’s reference.